Core Sanitation Equipment for Demanding Environments

A clean industrial environment is more than just a preference. It is a critical foundation for any successful operation. Proper sanitation directly impacts employee health and safety. It also boosts operational efficiency and protects your company’s reputation.

A clean industrial environment is more than just a preference. It is a critical foundation for any successful operation. Proper sanitation directly impacts employee health and safety. It also boosts operational efficiency and protects your company’s reputation.

We understand that sourcing the right industrial sanitation products can be complex. You need solutions that perform under tough conditions. You also need products that help you meet strict health and safety standards.

In this extensive guide, we will explore the essential types of industrial sanitation products. We will cover core equipment built for demanding environments. We will also look at specialized cleaning agents and deodorizers. Our aim is to help you understand the strategic value these products bring to your business. Advanced industrial sanitation products are engineered for performance and compliance, making them a wise investment.

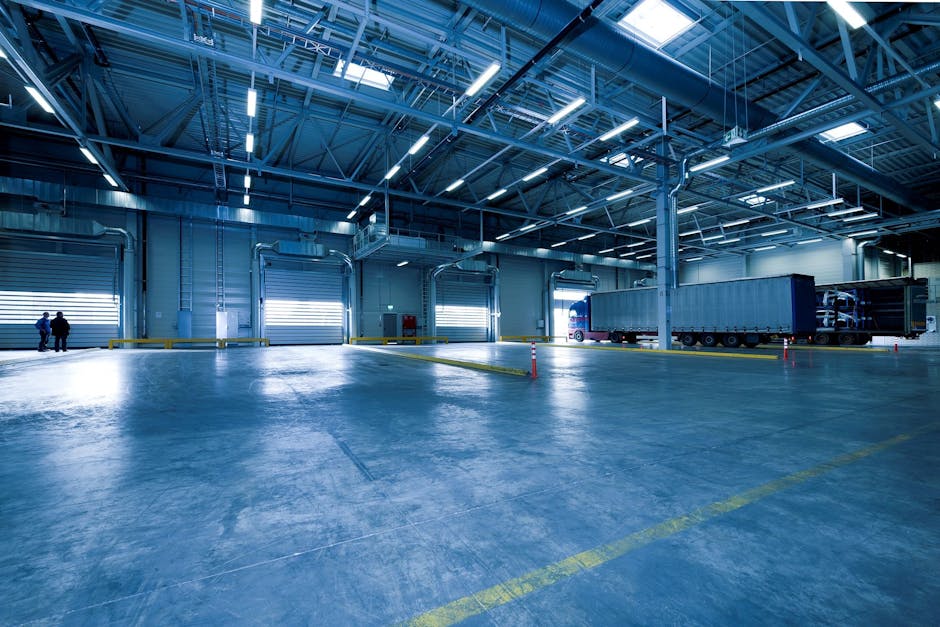

Industrial settings present unique challenges for sanitation. Unlike typical commercial spaces, industrial environments often involve heavy machinery, hazardous materials, high traffic, and exposure to extreme weather conditions. This demands sanitation equipment that isn’t just effective, but also incredibly robust and durable. When selecting core sanitation equipment for these demanding environments, we prioritize heavy-duty construction, suitability for high-traffic use, ease of service, and overall durability. These characteristics ensure that the equipment can withstand the rigors of daily industrial use, resist damage, and remain functional with minimal downtime, even in the harshest conditions. From remote construction sites to busy manufacturing plants, reliable sanitation infrastructure is paramount for maintaining hygiene and operational continuity.

High-Durability Portable Restrooms

In many industrial settings, particularly construction sites, remote work locations, or large outdoor facilities, traditional plumbing may not be available or practical. This is where high-durability portable restrooms become indispensable. These units are specifically engineered to endure the tough conditions inherent in industrial environments.

Their construction typically involves robust, high-density polyethylene (HDPE) materials, which are resistant to impacts, chemicals, and UV degradation. This ensures longevity and structural integrity even when exposed to harsh elements or rough handling. Vandal resistance is another critical feature, often incorporating reinforced doors, secure locking mechanisms, and graffiti-resistant surfaces to deter damage and maintain usability.

Effective ventilation systems are crucial for user comfort and odor control, especially in high-traffic areas. These systems help to circulate air, reducing unpleasant smells and improving the overall user experience. Tank capacity is a significant consideration, as larger tanks reduce the frequency of servicing, which is particularly beneficial for remote sites or those with limited access. A well-designed skid base ensures stability on uneven terrain and facilitates easy transport and placement using forklifts or cranes. Finally, the ease of cleaning is paramount. Interiors are designed with smooth, non-porous surfaces that can be quickly and thoroughly disinfected, ensuring optimal hygiene and efficient turnaround times between services. Investing in such durable units not only provides essential facilities but also minimizes maintenance costs and ensures consistent availability.

Mobile Hand Wash Stations

Beyond portable restrooms, mobile hand wash stations are a cornerstone of industrial sanitation, directly addressing critical hand hygiene needs and often mandated by health and safety regulations. In environments where workers handle various materials, operate machinery, or are exposed to contaminants, frequent and effective handwashing is vital to prevent the spread of germs, reduce skin irritations, and maintain overall health.

These stations are designed for mobility and ease of deployment, making them ideal for dynamic industrial sites. A key feature is hands-free operation, often achieved through foot-pump activated water flow or sensor technology. This minimizes cross-contamination, as users don’t need to touch faucet handles. Large water capacity tanks are essential to accommodate numerous washes between refills, ensuring that facilities remain available throughout shifts, especially in areas distant from water sources.

Equipped with integrated soap dispensers and paper towel dispensers, these stations provide a complete handwashing solution. The materials used are typically durable plastics or stainless steel, capable of withstanding industrial use and outdoor exposure. Compliance with regulations, such as OSHA standards for sanitation facilities, is a primary driver for their adoption. By providing readily accessible and hygienic handwashing facilities, businesses significantly contribute to employee health and safety, reducing absenteeism and enhancing overall workplace wellness.

Essential Deodorizers and Cleaning Agents

While robust equipment forms the physical backbone of industrial sanitation, the efficacy of any cleaning regimen ultimately hinges on the quality and suitability of the chemical solutions employed. Industrial environments often contend with unique and persistent challenges, including stubborn grease, oil, carbon deposits, and pervasive odors. Standard commercial or household cleaners simply aren’t formulated to tackle these heavy-duty demands.

Our focus is on providing chemical solutions that deliver superior odor control, efficient waste breakdown, and thorough surface cleaning, all while being safe for users and the environment where possible. These agents are designed to penetrate tough grime, neutralize odors at their source, and ensure surfaces are not just visually clean but hygienically so. The right combination of deodorizers and cleaning agents is crucial for maintaining a truly sanitary and pleasant industrial workspace.

High-Performance Deodorizing Solutions

Odor control is a major concern in many industrial settings, particularly in portable sanitation, waste management, and certain manufacturing processes. High-performance deodorizing solutions are specifically formulated to address these challenges, offering more than just masking agents.

A key innovation in this area is portion control. Whether in the form of pre-measured packets, effervescent tablets, or precisely dosed liquid concentrates, portion control ensures consistent performance, prevents overuse (leading to cost savings), and simplifies training for service technicians. This precision eliminates guesswork and guarantees optimal effectiveness with every application.

Many modern deodorizers use non-formaldehyde formulas, moving away from older, harsher chemicals. This shift is driven by environmental concerns and a focus on user safety, as non-formaldehyde options are generally more biodegradable and less irritating. Effervescent tablets offer convenience and a “drop-and-go” simplicity, quickly dissolving to release active ingredients. Liquid concentrates provide flexibility in dilution and application.

Beyond just fragrance, effective deodorizers incorporate waste digestion properties. These biological or chemical agents break down organic matter, reducing sludge buildup in holding tanks and minimizing the source of odors. Finally, long-lasting fragrances are crucial for maintaining a pleasant environment between services, ensuring that facilities remain fresh and inviting for users. The combination of these features creates a powerful solution for even the most challenging odor situations.

Specialized Industrial Cleaners and Degreasers

Industrial environments are characterized by unique types of grime and contamination that require specialized cleaning power. From heavy grease and oil in manufacturing to carbon deposits in automotive or exhaust-heavy operations, these substances demand cleaners far more potent than those found in consumer markets.

Specialized industrial cleaners and degreasers are formulated with heavy-duty formulas designed to penetrate, emulsify, and remove these stubborn residues effectively. Critical considerations include surface compatibility, ensuring that the powerful cleaning action doesn’t damage the underlying materials of equipment, floors, or vehicles. For instance, a cleaner designed for concrete might be too harsh for painted surfaces, while a specific degreaser might be needed for sensitive machinery components.

Grease removal and carbon deposit cleaning are common applications, requiring specific surfactants and solvents to break down these tough contaminants. As businesses increasingly prioritize environmental responsibility, the availability of biodegradable options is becoming more important. These products offer powerful cleaning performance while minimizing ecological impact. Furthermore, many industrial cleaners are offered as concentrated solutions, which provides significant cost savings and reduces storage and transportation needs. These concentrates are diluted on-site, allowing for flexible strength adjustments based on the severity of the cleaning task. Choosing the right specialized cleaner ensures efficient, safe, and effective maintenance of industrial assets.

The Strategic Value of High-Quality Industrial Sanitation Products

Investing in high-quality industrial sanitation products goes far beyond mere compliance or basic cleanliness. It’s a strategic business decision that yields significant returns in multiple areas. From tangible cost savings to improved employee morale and improved brand reputation, the benefits are multifaceted and contribute directly to a company’s bottom line and long-term success. A clean, safe, and well-maintained industrial environment is a hallmark of operational excellence, reflecting a commitment to quality and efficiency.

Enhancing Workplace Safety and Regulatory Compliance

Workplace safety and regulatory compliance are non-negotiable in any industrial operation, and high-quality sanitation products play a pivotal role in achieving both. A clean environment significantly reduces the risk of accidents. For instance, proper floor cleaners and degreasers prevent slip-and-fall incidents caused by oil, grease, or spills. This is one of the most important types of industrial sanitation products.

Effective sanitation also mitigates cross-contamination, which is particularly critical in industries like food processing, pharmaceuticals, or healthcare, where the spread of pathogens can have severe consequences. Specialized disinfectants and sanitizers ensure surfaces are not just clean but also free from harmful microorganisms.

Proper hazardous material management is integrated with sanitation practices, involving the safe handling, storage, and disposal of cleaning agents and the waste they help to remove. Adherence to health standards set by bodies like OSHA or the FDA is often directly tied to the cleanliness and hygiene of facilities and equipment. By proactively investing in superior sanitation, businesses protect their employees from illness and injury, reduce liability, and ensure seamless operations free from regulatory penalties. This commitment to employee well-being fosters a healthier, more productive workforce and strengthens the company’s reputation as a responsible employer.

Boosting Productivity and Protecting Assets

The impact of industrial sanitation extends directly to a company’s productivity and the longevity of its valuable assets. Regularly cleaned and maintained equipment, for example, experiences significantly less wear and tear. This translates to increased equipment longevity, as dirt, dust, and corrosive substances are removed before they can cause damage or premature failure. This proactive maintenance can extend the lifespan of machinery by up to 30%, drastically reducing replacement costs and capital expenditure.

Furthermore, a clean and organized workspace leads to reduced downtime. When equipment functions optimally and the environment is free from obstructions or hazards, operational interruptions due to breakdowns or accidents are minimized. This ensures continuous production and maximizes output. A healthy workforce, supported by excellent hygiene standards, experiences fewer sick days and higher morale, directly translating to consistent and higher productivity. Employees are more focused and efficient in a clean, safe, and pleasant environment.

Effective industrial sanitation is a powerful strategy for asset protection. It safeguards not only machinery and infrastructure but also the health of the workforce, which is a company’s most valuable asset.

Frequently Asked Questions about Sourcing Industrial Sanitation Products

When it comes to outfitting an industrial operation with the right sanitation solutions, many questions arise. The unique demands of industrial environments mean that standard commercial products often fall short. Here, we address some of the most common inquiries to help you make informed decisions when sourcing industrial sanitation products.

What distinguishes industrial-grade sanitation products from commercial ones?

The fundamental difference lies in their design, durability, and chemical potency, custom to the unique challenges of their respective environments.

Industrial-grade products are built for extreme conditions. They feature:

- Durability: Constructed from heavy-duty, robust materials (e.g., thick-gauge plastics, reinforced metals) to withstand constant use, rough handling, and harsh chemicals. They are designed for longevity in tough settings.

- Hazard Resistance: Engineered to operate safely and effectively around industrial hazards like high temperatures, corrosive substances, heavy machinery, and continuous vibration.

- Scale of Application: Designed for large-scale operations, covering vast areas, or cleaning massive equipment. Think high-capacity tanks, wide cleaning paths, and powerful motors.

- Chemical Potency: Cleaning agents and deodorizers are formulated with higher concentrations of active ingredients and specialized compounds to tackle industrial-specific contaminants like heavy grease, carbon buildup, industrial paints, and persistent odors.

- Specialized Design: Often feature specific functionalities for industrial tasks, such as anti-static properties, metal detectability (for food processing), or compatibility with specific industrial machinery.

- High-Traffic Suitability: Built to endure continuous use by a large workforce or in environments with constant movement and activity.

Commercial products, in contrast, are typically designed for lighter, more routine cleaning in public or office spaces. They prioritize aesthetics, ease of use for general cleaning tasks, and cost-effectiveness for less demanding environments. While effective for their intended use, they lack the resilience, power, and specialized features required for true industrial applications.

How do portion-controlled products benefit a rental operation?

For rental operations, particularly those dealing with portable sanitation units, portion-controlled products offer a multitude of benefits that streamline operations and improve profitability.

- Cost Control: Pre-measured doses eliminate guesswork and prevent overuse of expensive chemicals. This leads to predictable chemical consumption and significant savings over time, as there’s no wasted product.

- Inventory Management: Standardized units simplify inventory tracking, ordering, and storage. It’s easier to know exactly how much product is needed and on hand.

- Service Consistency: Every unit receives the exact same, optimal amount of chemical, ensuring consistent performance in odor control and waste breakdown across your entire fleet. This leads to higher customer satisfaction.

- Reduced Waste: No spills, no over-pouring, and no partially used containers mean less chemical waste and fewer disposal issues, contributing to both environmental responsibility and cost efficiency.

- Ease of Training: New technicians can quickly learn and implement the correct dosing procedure, reducing errors and ensuring that all services are performed to the same high standard.

- Accurate Dosing: Guarantees that the product’s efficacy is maximized, as it’s applied at the manufacturer’s recommended concentration, leading to superior results in even challenging conditions.

By embracing portion-controlled solutions, rental operations can achieve greater efficiency, reduce operational costs, and deliver a more consistent, high-quality service to their clients.

What are key features to look for in products for extreme weather conditions?

Industrial operations often extend into environments with extreme temperatures, from freezing winters to scorching summers. Sanitation products used in these conditions must be specifically formulated and designed to maintain their efficacy and integrity.

- Brine Compatibility for Cold: For liquid deodorizers and cleaning agents, the ability to dissolve or remain stable in brine (saltwater) is crucial. This prevents freezing and ensures the product can be effectively used in portable restrooms even when temperatures drop below freezing, avoiding the need for additional steps or specialized heating.

- Freeze Protection: Equipment components, especially those involving water lines or tanks, should be designed with built-in freeze protection or made from materials that can withstand ice expansion without cracking. Deodorizers themselves should have a low freezing point.

- High-Heat Formulas: In hot climates, products must resist degradation from high temperatures. Deodorizers, for instance, need formulas that maintain their effectiveness and fragrance longevity even when exposed to intense heat, preventing rapid evaporation or breakdown.

- Time-Released Fragrances: Extreme temperatures can accelerate the dissipation of fragrances. Products with time-released or encapsulated fragrance technologies ensure a consistent and long-lasting scent profile, providing continuous odor control regardless of temperature fluctuations.

- UV-Resistant Materials: For outdoor equipment like portable restrooms and hand wash stations, materials must be UV-stabilized to prevent degradation, fading, and brittleness caused by prolonged exposure to sunlight. This maintains the structural integrity and aesthetic appeal of the units over time.

Selecting products with these features ensures reliable performance and durability, minimizing maintenance issues and maximizing service quality in challenging climates.

Conclusion

The importance of industrial sanitation products cannot be overstated. They are not merely an operational expense but a strategic investment that underpins the success and sustainability of any industrial enterprise. From ensuring the health and safety of your workforce to preserving valuable assets and enhancing overall productivity, the right sanitation solutions are a cornerstone of operational excellence.

By prioritizing high-durability equipment and advanced chemical agents, businesses can cultivate a robust safety culture, build greater customer trust, and realize significant long-term value. Choosing the right sanitation partner who understands the unique demands of your industry and provides custom, high-performance products is paramount. Accept the power of effective industrial sanitation, and watch your business thrive in a cleaner, safer, and more productive environment.